Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

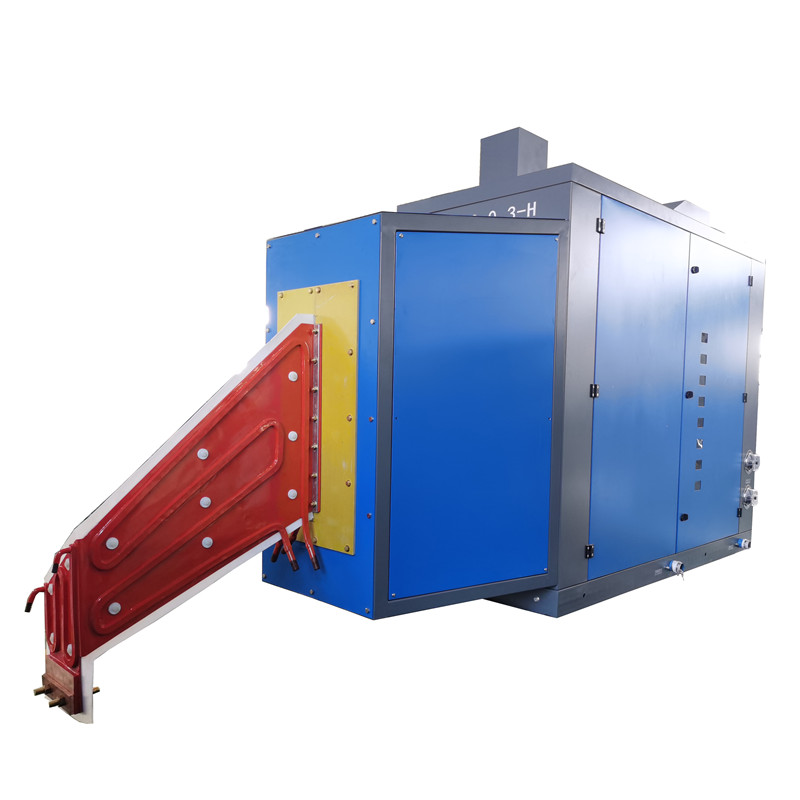

China New Product Igbt Solid State Welder - 300KW Parallel circuit IGBT Integrated Solid State H.F. Welder – Mingshuo

China New Product Igbt Solid State Welder - 300KW Parallel circuit IGBT Integrated Solid State H.F. Welder – Mingshuo Detail:

| DC power | 10~400kw |

| Inverter frequency | 50~400kHz |

| Material heated | all kinds of carbon steel,non- ferrous |

| Heating mode | pipe heating ,wire heating, bar heating ,plate heating,bearing heating,gear heating,plane heating. |

| Heating methods | quenching ,heating penetration ,brazing. |

| Main Design Index of Solid State H.F. Welder | |

| Output power | 300kw |

| Rating Voltage | 230V |

| Rating Current | 1500A |

| Design Frequency | 250~350kHz |

| Electricity Efficiency | ≥90% |

| Pipe material | carbon steel |

| Pipe diameter | 40-100mm |

| Pipe wall thickness | 1.0-4.0mm |

| Welding Mode | Induction type of High Frequency Solid State Welding Machine |

| Cooling Mode | Use Air-Water cooler system or water water cooling system to cool induction type 300kw solid state high frequency welder |

| After sale service | Online support,Field installation,commissioning and training,Filed maintenance and repair service |

①Low voltage and high current working mode

②Two-stage LC filter, the output current is more stable.

③MOSFET is used as the inverter element.

④The control circuit is controlled by a microcomputer, and the rectifier board has two microcomputers to complete digital trigger and control functions.

⑤The equipment has water pressure, water temperature, over-voltage, over-current, phase loss, phase sequence protection, short circuit, open circuit protection, etc., and provides digital display.

⑥The inverter circuit has a frequency tracking function, so that the trigger frequency is always approximately equal to the tank circuit frequency.

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of China New Product Igbt Solid State Welder - 300KW Parallel circuit IGBT Integrated Solid State H.F. Welder – Mingshuo , The product will supply to all over the world, such as: Russia, Costa rica, Doha, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us