Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

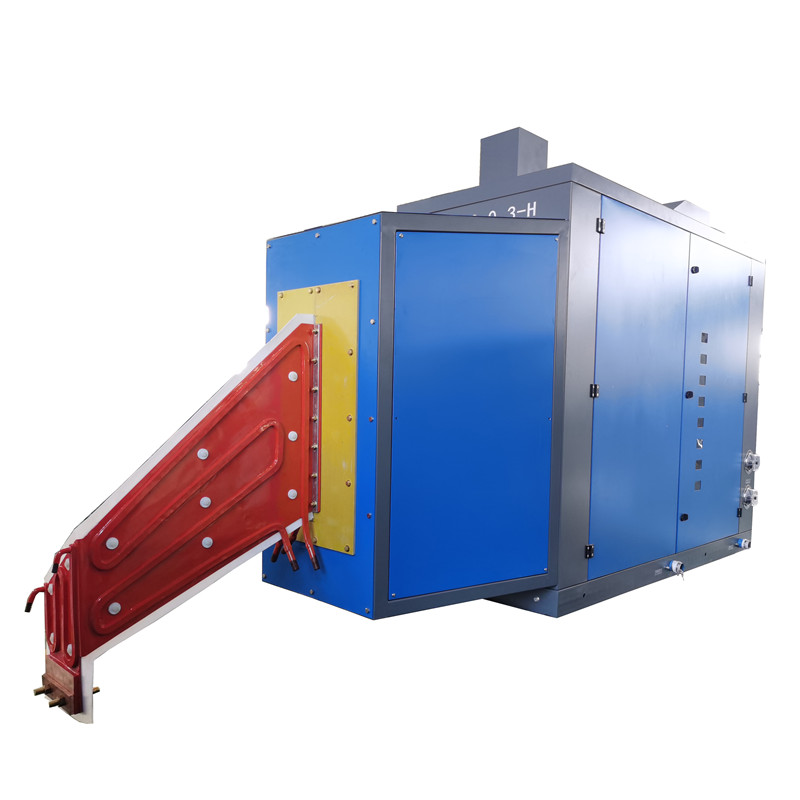

Competitive Price for Switch Rectifying Welder - Steel Welded Tube Mill Equipment Ornamental Iron Pipes Machinery 400KW induction heating steel welder – Mingshuo

Competitive Price for Switch Rectifying Welder - Steel Welded Tube Mill Equipment Ornamental Iron Pipes Machinery 400KW induction heating steel welder – Mingshuo Detail:

Diode all wave rectifying add IGBT chopping to replace SCR rectifying, to improving the power factor.Save 15%~25% of electric power.

The inverter part consists of MOSFET single-phase invert bridges connected in Parallel.

| Main Design Index of Solid State H.F. Welder | |

| Output power | 400kw |

| Rating Voltage | 230V |

| Rating Current | 2000A |

| Design Frequency | 200~300kHz |

| Electricity Efficiency | ≥90% |

| Pipe material | Carbon steel |

| Pipe diameter | 60-140mm |

| Pipe wall thickness | 1.0-5.0mm |

| Welding Mode | contact or dual type of High Frequency Solid State Welding Machine |

| Cooling Mode | Use Water-Water cooler system to cool induction type 400kw solid state high frequency welder |

| After sale service | Online support,Field installation,commissioning and training,Filed maintenance and repair service |

| Welding material | stainless steel aluminum pipe ,cooper pipe |

1. Diode all wave rectifying add IGBT chopping to replace SCR rectifying,it’s improving the power factor;The DC part and inverter part into one cabinet,which reduce the waterway and circuit between the cabinets,which is effectively avoiding the electrical interference and reducing the installation time.

2. we adopt sub-resonance,no-welding transformer output mode and make resonance directly by tank resonance capacitor (low voltage) and inductor to achieve steel pipe welding power transmission by output lead.

3. Use sealed box and install overhead air conditioning.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Competitive Price for Switch Rectifying Welder - Steel Welded Tube Mill Equipment Ornamental Iron Pipes Machinery 400KW induction heating steel welder – Mingshuo , The product will supply to all over the world, such as: Cyprus, Leicester, United Arab Emirates, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!