Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

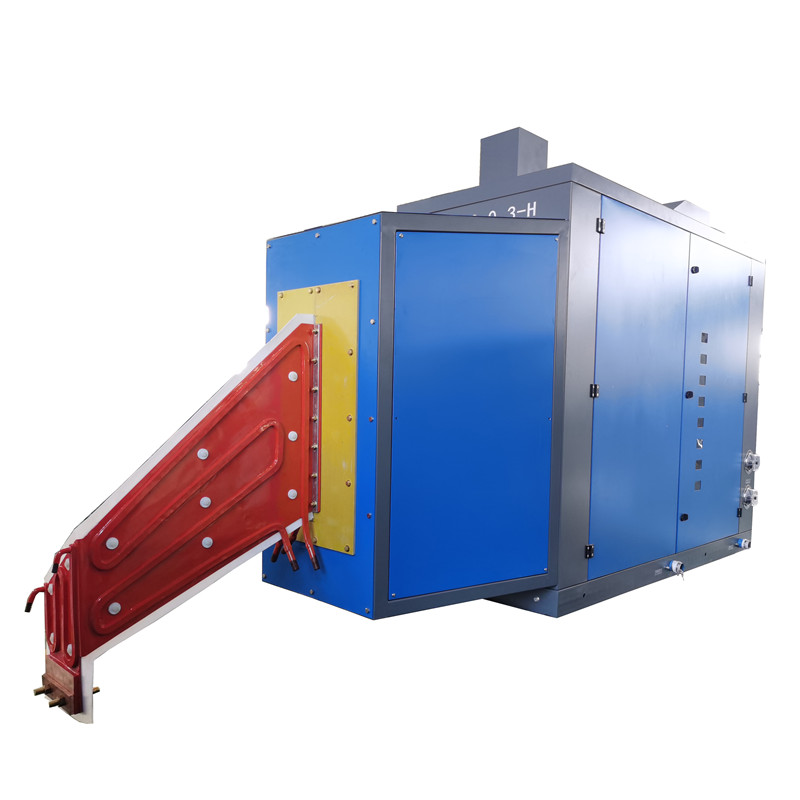

OEM Customized China Power Module For Solid State High Frequency Welder - Steel Welded Tube Mill Equipment Ornamental Iron Pipes Machinery 400KW induction heating steel welder – Mingshuo

OEM Customized China Power Module For Solid State High Frequency Welder - Steel Welded Tube Mill Equipment Ornamental Iron Pipes Machinery 400KW induction heating steel welder – Mingshuo Detail:

Diode all wave rectifying add IGBT chopping to replace SCR rectifying, to improving the power factor.Save 15%~25% of electric power.

The inverter part consists of MOSFET single-phase invert bridges connected in Parallel.

| Main Design Index of Solid State H.F. Welder | |

| Output power | 400kw |

| Rating Voltage | 230V |

| Rating Current | 2000A |

| Design Frequency | 200~300kHz |

| Electricity Efficiency | ≥90% |

| Pipe material | Carbon steel |

| Pipe diameter | 60-140mm |

| Pipe wall thickness | 1.0-5.0mm |

| Welding Mode | contact or dual type of High Frequency Solid State Welding Machine |

| Cooling Mode | Use Water-Water cooler system to cool induction type 400kw solid state high frequency welder |

| After sale service | Online support,Field installation,commissioning and training,Filed maintenance and repair service |

| Welding material | stainless steel aluminum pipe ,cooper pipe |

1. Diode all wave rectifying add IGBT chopping to replace SCR rectifying,it’s improving the power factor;The DC part and inverter part into one cabinet,which reduce the waterway and circuit between the cabinets,which is effectively avoiding the electrical interference and reducing the installation time.

2. we adopt sub-resonance,no-welding transformer output mode and make resonance directly by tank resonance capacitor (low voltage) and inductor to achieve steel pipe welding power transmission by output lead.

3. Use sealed box and install overhead air conditioning.

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for OEM Customized China Power Module For Solid State High Frequency Welder - Steel Welded Tube Mill Equipment Ornamental Iron Pipes Machinery 400KW induction heating steel welder – Mingshuo , The product will supply to all over the world, such as: belarus, Sri Lanka, Paris, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.