Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

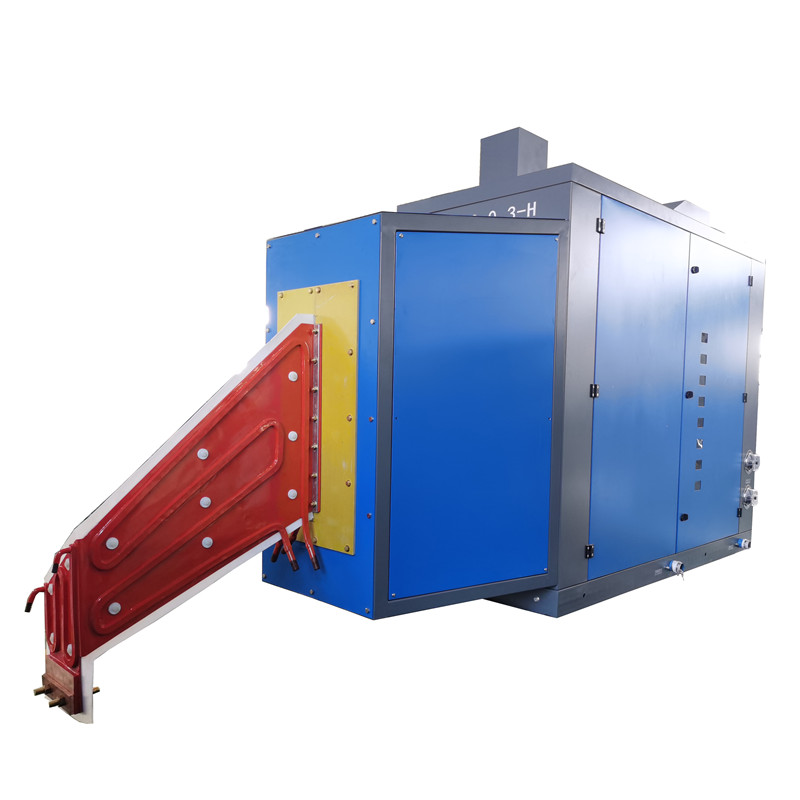

OEM Customized Galvanized Steel Tube Welder - Parallel circuit 800kw Solid state hf welder for tube mill – Mingshuo

OEM Customized Galvanized Steel Tube Welder - Parallel circuit 800kw Solid state hf welder for tube mill – Mingshuo Detail:

1. Low voltage and high current working mode

2.Two-stage LC filter, the output current is more stable.

3. MOSFET is used as the inverter element.

| Pipe material | Carbon steel/aluminium steel/stainless steel/ERW/Galvanized/Iron/copper steel |

| Pipe shape | Round,Square, Rectangular,H-shape,Special shape |

| Main Design Index of Solid State H.F. Welder | |

| Output power | 800kw |

| Rating Voltage | 230V |

| Rating Current | 4000A |

| Design Frequency | 150~250kHz |

| Electricity Efficiency | ≥90% |

| Pipe material | Carbon steel |

| Pipe diameter | 100-250 mm |

| Pipe wall thickness | 2.0-10.0mm |

| Welding Mode | contact/dual type of High Frequency Solid State Welding Machine |

| Cooling Mode | Use Water-Water cooler system to cool induction type 800kw solid state high frequency welder |

| After sale service | Online support,Field installation,commissioning and training,Filed maintenance and repair service |

1. The control circuit is controlled by a microcomputer, and the rectifier board has two microcomputers to complete digital trigger and control functions.

2. The equipment has water pressure, water temperature, over voltage, over current, phase loss, phase sequence protection, short circuit, open circuit protection, etc., and provides digital display.

3. The inverter circuit has a frequency tracking function, so that the trigger frequency is always approximately equal to the tank circuit frequency.

4 With frequency display function, it is displayed by a four-digit digital tube, and the display accuracy is ±100HZ. Normal, adjust the tank circuit or check the feedback signal.

High-frequency welding machines can be used for welding alloy tools, such as alloy turning tools, milling cutters, planers, saw blades, reamers, boring cutters, etc.

3-D Adjustable Bracket

2-D Adjustable Bracket

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for OEM Customized Galvanized Steel Tube Welder - Parallel circuit 800kw Solid state hf welder for tube mill – Mingshuo , The product will supply to all over the world, such as: Milan, Marseille, Qatar, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.