Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

OEM/ODM Supplier Mosfet Inveter Cabinet - Central Console & DC Drive Cabinet – Mingshuo

OEM/ODM Supplier Mosfet Inveter Cabinet - Central Console & DC Drive Cabinet – Mingshuo Detail:

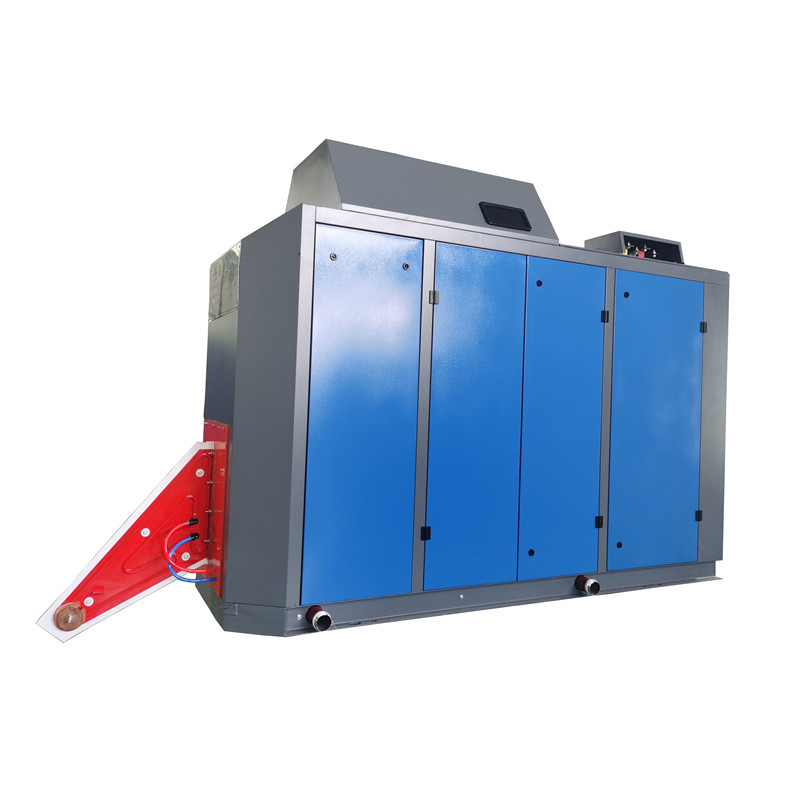

Dc Drive Cabinet

DC Drive cabinet has 3 series:computer-control stimulation mode,all-digital Euro Drive original mode and all-digital Euro Drive expansion mode. Adopt speed-current double close-loop control,with merits of wide speed regulation range,super dynamic performance,multiple motors linkage etc.

This equipment abroad apply to light industrial,paper making ,plastic, pipe and tube welding ,chemical ,cement etc.

Voltage grade:460v/230v Current level:100A~3000A

|

NO. |

Model |

Spec |

Rated power |

|

|

Rated current |

Rated voltage |

|||

|

1 |

OL-70A/460V |

70A |

460V |

30KW |

|

2 |

OL-110A/460V |

110A |

460V |

45KW |

|

3 |

OL-150A/460V |

150A |

460V |

60KW |

|

4 |

OL-180A/460V |

180A |

460V |

75KW |

|

5 |

OL-270A/460V |

270A |

460V |

110KW |

|

6 |

OL-360A/460V |

360A |

460V |

150KW |

|

7 |

OL-500A/460V |

500A |

460V |

190KW |

|

8 |

OL-800A/460V |

800A |

460V |

330KW |

Driving and speed regulation of DC motor, high precision DC power supply.

OL series of DC drive is mainly used to drive DC motor, and widely applied to welding tube mill industry. Its unique weak magnetic control circuit can ensure a wide speed regulating scope of DC motor. Its steady digital DC control circuit can not only make the DC drive has a stable work and strong anti-interference ability, but also has a good user interface which is convenient for operation.DC drive includes: 3-phase 6 pulse SCR rectifier, SCR excitation control module, full digital DC control circuit.

⑴ Perfect structure design

①.Integration design of DC drive with the features of compact structure and small size. Original type or extension type structure is optional.

②.Main loop thyristor adopts high efficiency air cooling radiator which is convenient for installation and maintenance.

③High standard electromagnetism compatibility design, electromagnetism radiation meets national standard.

④.Closed cabinet design, meeting rigor environmental requirements on site.

⑵ Full digital control system

①.Adopt 590DIGITAL series full digital controller to realize precise synchronous trigger with high control precision of motor speed and rapid response speed.

②Motor operation parameter adopts digital menu setting, which is convenient and flexible with good HMI.

③The power supply has perfect protection function with reliable working and low failure rate.

equipment selection*

1.Select DC drive model as per rated voltage and rated power of DC motor.

2. The DC drive needs to reserve 20% power margin.

Central Console

The console achieves remote control and power regulation of solid-state H.F welder,installed with LCD;also it has indicators of armature voltage,field voltage on DC drive cabinet and indicators of DC voltage,DC current on welder.Installation of power-speed closed loop control function is optional.The console has design difference according to different types and quantities of matching DC drive cabinet.

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for OEM/ODM Supplier Mosfet Inveter Cabinet - Central Console & DC Drive Cabinet – Mingshuo , The product will supply to all over the world, such as: luzern, Slovakia, United Arab emirates, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!